Ìý

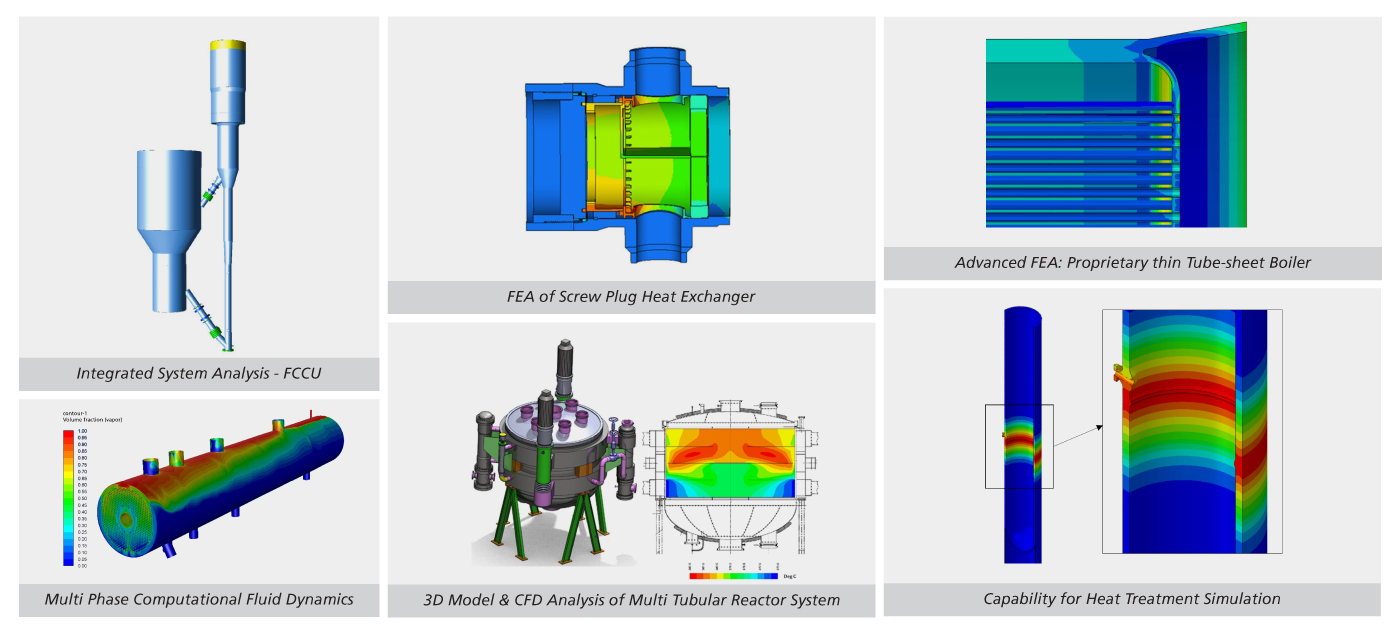

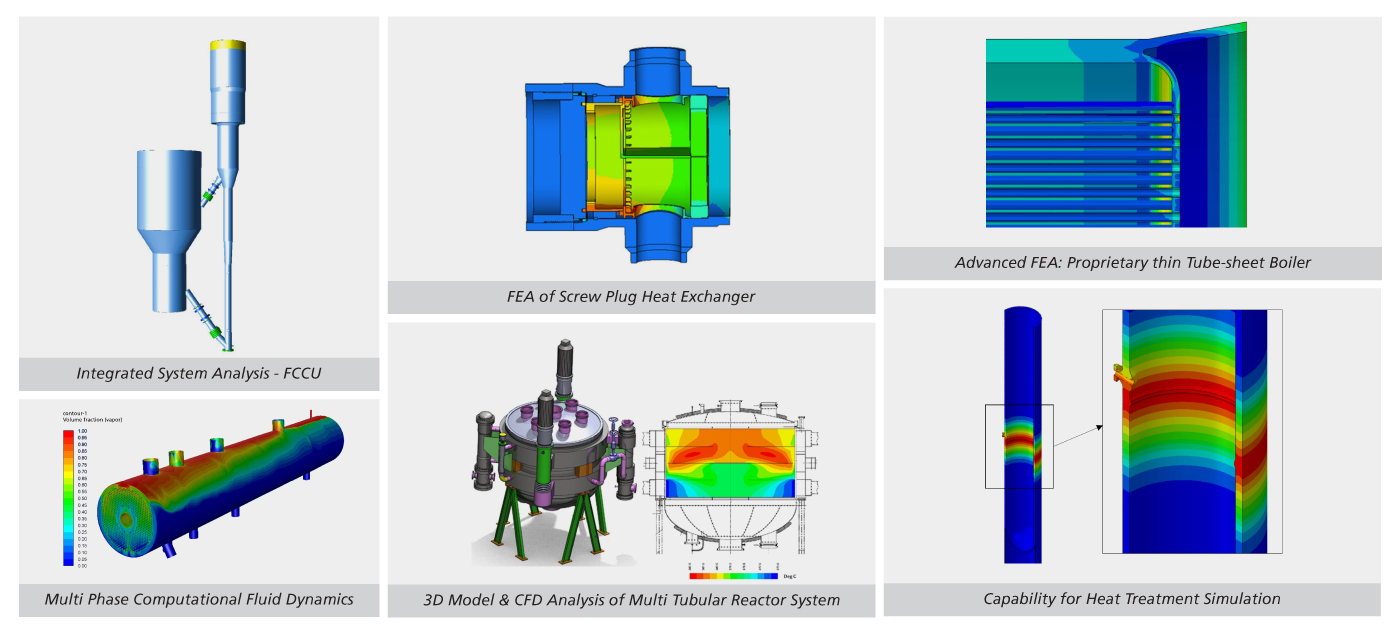

L&T’s engineering capabilities are geared to design equipment as per customer specific requirements, and international codes and standards. Fabrication drawings for critical equipment are generated through 3D automation which have been developed in house.

The perpetual endeavour of design engineers is to generate optimum solutions leading to lowest capital and operating costs.

Technology Solution from a Single Source

| Mechanical |

Thermal |

- Design to International-Codes & Standards

- ASME Sec. I, III & VIII

- EN 13445

- PD5500 - British

- IBR

- AS1210 - Australian

- ADM - German

- KTA - German

- JIS - Japanese

- Stoomwezen - The Netherlands

- TEMA Standards

- JMA Standards

- GB 150 - Chinese

- Wind & Seismic Analysis

- Automated

- Modelling - 2D/3D

Ìý

|

- Members of HTFS & HTRI Design of Equipment

- All types of Shell & Tube Exchangers

- Screwplug Closure (Breech lock)

- HP Heat Exchangers

- Helixchanger/Helitower

- Transfer Line Exchangers

- Nuclear Steam Generators

- Multi Tubular Reactors

- Shell & Tube LNG Vaporisers

- Heat Transfer Systems Design & Analysis

- Waste Heat Boiler Systems

- Molten Salt Bath ReactorÌý(MSBR) Systems

- Vaporiser Systems

|

| Analysis |

Special |

- Finite Element Analysis

- Static & Dynamic

- Linear & Non-linear

- Response Spectra Analysis

- Thermo-structural

- Steady state & transient

- Buckling

- Fatigue & Fracture

- Creep & Creep-Fatigue Interaction

- Computational Fluid Dynamics

- Conjugate Heat Transfer

- Single & two-phase flows

- Reactor Chemical Kinetics

- Particle Dynamics

- Piping Flexibility

- Flow Induced Vibration (FIV)

- Integrated System Analysis

- Lifting & Transportation

|

- Fluid Structure Interaction Analysis (FSI)

- Simulation of weld induced distortion and stress pattern

- Analysis for metal

- Chemical Process Simulation

- Collaborative Research & Process Developmen

- Failure Analysis

- Analysis and engineering for Site Fabrication and Revamps

- Experimental Stress Analysis

- Destructive / Non-destructive Testing

|